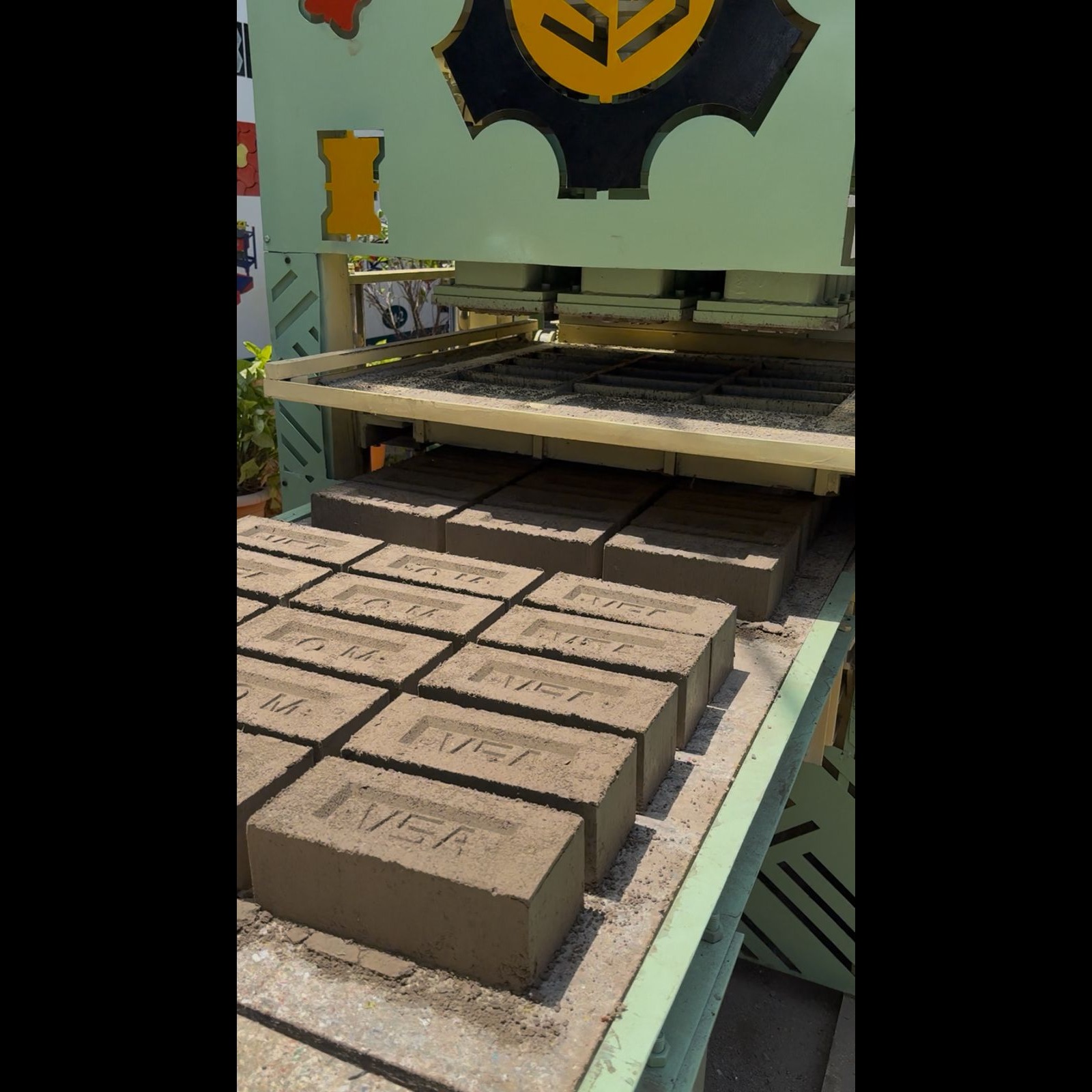

A fly ash brick machine is a high-tech device used to produce fly ash bricks, which are an environmentally friendly and cost-effective alternative to traditional clay bricks

How Fly Ash Brick Machines Work:

Fly ash brick machines work by combining raw materials like fly ash, lime, and gypsum, and then compressing them into the desired brick shape and size using hydraulic pressure. They are available in various configurations and levels of automation.

Types of Fly Ash Brick Machines:

Fully Automatic: These machines require minimal manual labor as they handle tasks from material feeding to brick creation and stacking. They often utilize PLC control technology for efficiency and accuracy.

Semi-Automatic: These machines require some manual intervention, such as loading raw materials and removing finished bricks from the molds. They are typically less expensive and suitable for smaller-scale production.

Hydraulic: These machines are known for their high production capacity and use hydraulic pressure to create strong and durable bricks with less water consumption.

Manual: These are the simplest type, requiring the most manual labor, and are best suited for low-volume production.